|

The top motor isn't working.

Moving the switch finds no noise from the motor, no deflection

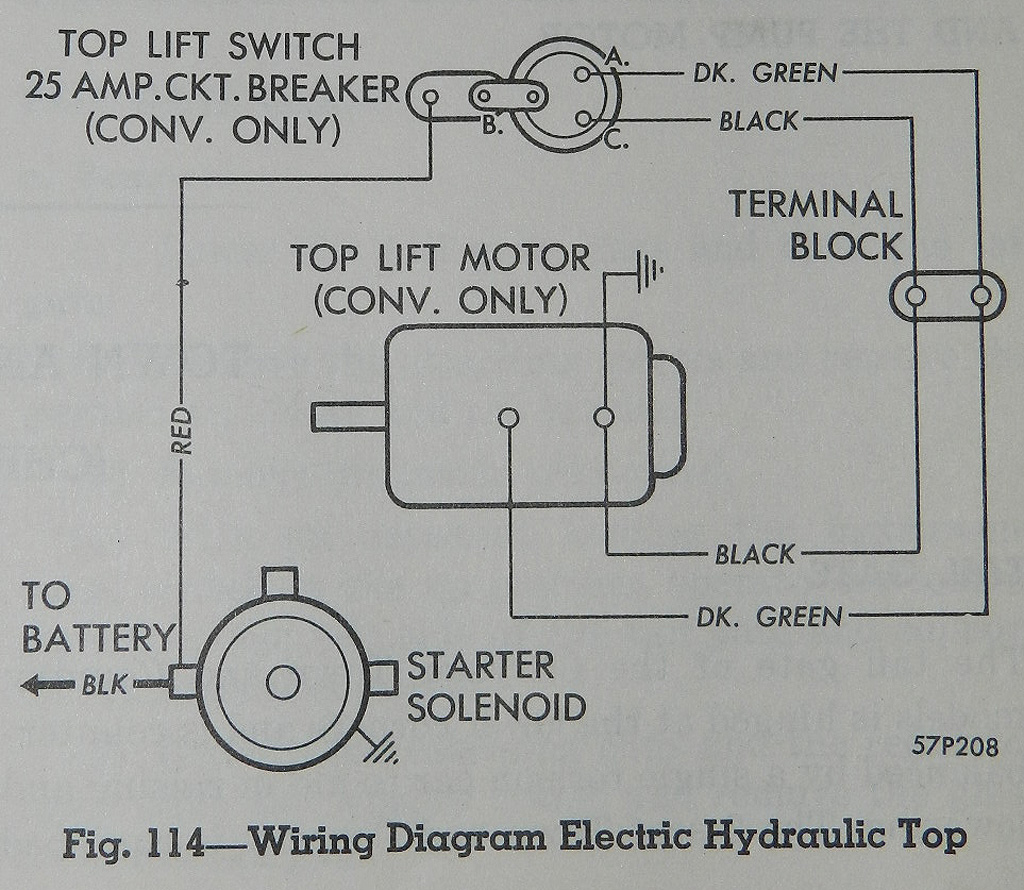

from the ammeter. Let's check the service manual for a wiring diagram.

If you do what I did and check the electrical portion of the manual (section 8)

you won't find it. It is in section 23, "Body And Sheet Metal", on page 65

as shown here.

On the next page you find the instructions:

and then this page for

Testing Wires Between the Control Switch

and the Top Motor

and here is an enlargement of the wiring diagram

We tested the switch and it is OK. The feed wire to the switch has volts. Now we need

to move to the pump. Before leaving the switch, might as well clean and polish

and re-letter the printing. I used Testor's white enamel, applied liberally with a fine

brush. Let sit for 15 minutes and wipe the excess off with a towel and alcohol.

A test light on the connection of the feed wires at the pump shows we have

juice to the motor, and says the motor is bad. Hydro-E-Lectric

has new units along with mounting buttons and hose kits. The trick will be access to the motor.

The top boot is held to the body with 3 Phillips screws on the drain plate. With that removed,

the boot material exposes the motor way up by the rear seat partition.

You can see the pump motor. In this picture I have it loosened from its mount

and turned sideways. As it is, I can get to the hose connections at the motor

and I can disconnect the electric feed wires. What I can't do is access the Philips head

screw that holds the ground wire. That screw goes into the metal cross braces, from the

interior side, and is covered by the seat back panel. I thought about cutting the ground

wire and connecting the new ground wire to a new ground. Another day and time, I would have.

Here I decided to get to that ground screw from the interior. That meant loosening the center

console enough to free the separator board, tilting the board forward and accessing the screw.

That exercise did the trick and the pump motor was removed.

I decided not to remove and replace

the hoses since they were still flexible and likely new when Ed had the car restored 20-ish years ago.

The new pump motor arrived from Hydro-E-Lectric. Installation was straight forward although

I was lucky that the system had not lost any fluid and I did not have to deal with filling the reservoir or

getting the air out of the system. They recommend transmission

fluid for the system and that is what I used. Back in the day, Chrysler used brake fluid and that was OK

until things started to leak -- brake fluid being corrosive.

Click here for a video of the pump motor removal.

|