Golden Lion Grrrages

1962 Chrysler 300 H Convertible

Page3

|

The passenger side A pillar molding has two dents. I found a very nice spare in storage

and brought it over. I might as well try to remove the dents in the

original piece. Doggone, they worked out so nice I reinstalled the original piece. I used

hammer handles -- the oval sections, and tapped on those pieces of wood with the

outer section of the molding supported on softwood.

We removed the front tires and brake drums. Ball joints test good, good idler arm and center link and tie rods.

Both wheels show worn wheel bearings but the brakes shoes, cylinders and drums have lots of life.

We removed inner and outer races front wheels. Some were hard to pound out -- a matter of the

right size hammer and the right angle on the punch. We installed new races by using the old wheel bearings for install.

Put the old bearings in the new races and it gives you a lot of surface to pound on.

New front wheel seals, grease, reassemble with the Chrysler recommended bearing procedure (90 in-lbs, back

off nut one slot).

The front door panels came off so we can rebuild the power window motors. Both doors had vapor barriers.

The passenger door will need to be replaced due to rust, the driver side is fine. The driver door has been

cut by a previous owner to access the window motor. You can see the motor had broken the transmission

mount and had been repaired. We will put anchors on both motors so the impact from door closing does not

result in the motors stressing the transmissions.

The driver side panel was torn and damaged along the lower edge. The cardboard backer was weak

in this area as well. New door panels are not available. I got the idea to make this panel presentable by

adding a third chrome strip. I had a spare piece. The strip is held by a series of sharp pointed teeth which

easily penetrate the board. By using a strip identical to one already on the panel, it almost looks like it

was factory. In any case, it does a great job of covering the torn area and protecting the bottom edge.

The fuel line from the tank had been patched. A new one came from InLine Tube. It was about $135, a large

part of that was the shipping cost -- it doesn't weight much but it comes in an over-size box. It has a large

radius bend that is easily straightened. Installation was quick and easy. I had to replace several of the

clips which hold the line to the body. There are three sizes. I needed several medium and one large to

get the fit I needed. These were from Gary Goers. Probably Quirey has them now.

The neutral safety switch had been bypassed. For the longest time

I have been

unable to successfully test a neutral safety switch. Every switch I tested acted the same:

I always had continuity from the wire post to the spring loaded pin, no matter what position

the pin was in. And I always had no continuity from the wire post to the body. I never could

get the switch to be off in one position and off in another, which is what I expect a switch to do.

Aha! The answer from John Grady. It is not a switch. It is a spring loaded grounding pin. See

more here.

I have been

unable to successfully test a neutral safety switch. Every switch I tested acted the same:

I always had continuity from the wire post to the spring loaded pin, no matter what position

the pin was in. And I always had no continuity from the wire post to the body. I never could

get the switch to be off in one position and off in another, which is what I expect a switch to do.

Aha! The answer from John Grady. It is not a switch. It is a spring loaded grounding pin. See

more here.

The new license plates arrived and were installed.

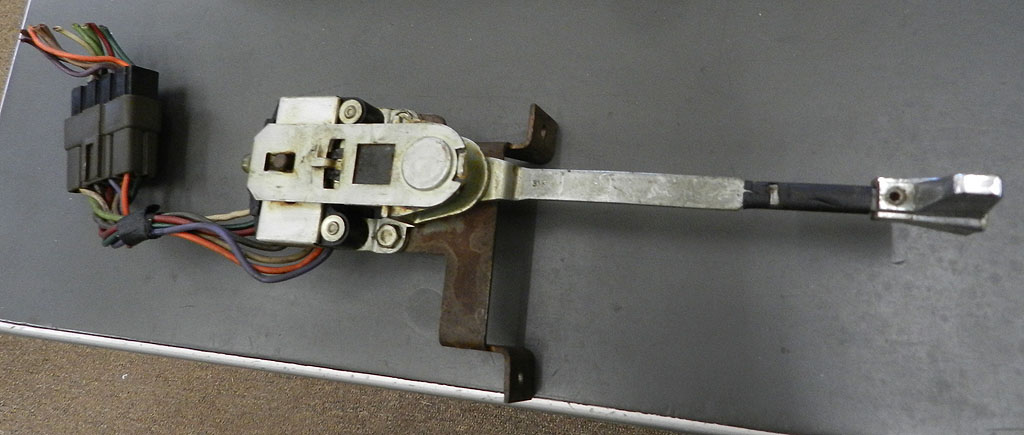

The turn signal switch was stiff and hard to move. It would not latch in either the right

or left position. I removed the bezel and sprayed lube through the small slots hoping it would

get to the switch. Forget that idea.

The parts of the switch that need lube are on the bottom and you won't get the spray to those

areas. This picture shows the switch. It is upside down. When installed, that pin and roller and slider

are on the under side. You might be able to spray lube up into the bottom of the switch from the

back side of the dash but access is tough. I chose to remove the switch.

Two nuts on the switch, two nuts on the transmission button block and you can wrestle

the switch out. Then I was able to get lube into the slider section. The

lever now moves freely and latches. Installation was quick (often it isn't) and

it works as it should.

The parts of the switch that need lube are on the bottom and you won't get the spray to those

areas. This picture shows the switch. It is upside down. When installed, that pin and roller and slider

are on the under side. You might be able to spray lube up into the bottom of the switch from the

back side of the dash but access is tough. I chose to remove the switch.

Two nuts on the switch, two nuts on the transmission button block and you can wrestle

the switch out. Then I was able to get lube into the slider section. The

lever now moves freely and latches. Installation was quick (often it isn't) and

it works as it should.

The driver front fender has significant Bondo repair. The passenger side fender is fine. I have a replacement in much better shape for the driver so set about in the removal. The grille has to come out. I had forgotten how

difficult the H grille is. The mounting nuts are not visible, and the grille mesh is full of sharp edges. This car

has AC, so the condensor is there with its thousands of sharp edges. Plus, there is little room, even for

my small boney hands. It is like working on a cheese grater.

The fender is not held on by too many bolts, and most are accessible. I left the inner fender intact, which

makes the job easier. It took about 3 hours working alone and the fender was off. I was pleased to see little

rust on the inner fender, chassis, and firewall areas.

One of the things I like is properly shaped tail pipes. When you get new pipes, the ends of the tail

pipes are just square cuts. It isn't all that much work to take a cut off wheel and get the

proper shape. The idea is to cut the underside pretty much horizontal. Take a yard stick, approximate

horizontal, make a mark on the pipe with a Sharpie and see where the cut ends up. There is a lot of "artistic leeway"

allowed here. In this picture you can see the far pipe, not modified and the nearer pipe has the cut.

A 40 grit flap wheel on your grinder will let you quickly compensate for unintended designs.

I decided to tackle the passenger door project. I bought over the very nice shell from the shop, compared, took dimensions, satisfied it was a 62. Removed two window shaft retainer clips (a bit hard to do), top stops, and the side glass slides out the top. The regulator has only a few bolts and is easy to snake out. Now I could get a good look at the regulator spring. It is not cracked or broken but it has lost its strength. I had a 64 regulator handy thinking I could swap springs but they are not the same size. I had a regulator from a 62 with manual windows and doggone, that spring is still not big enough. I later found a 62 power window regulator which had the proper parts.

The door latch screws came loose easily so removed the latch, outer handle, and vent window. I used the engine hoist to support the door before removing the two sets of 3 bolts from the hinge arms. The new shell, being empty, is light and installed easily. It opens and closes without problem but needs a little alignment which is in section 23 of the service manual. Fore and aft adjustments are only in the door bolt plates. Up and down and in and out are only in the body hinge plates.

Terrible winter weather February 7th, 2026. Minus 2 degrees with snow and wind, drifting roads, windchill minus 20. Comparing the old and new door I see I need to remove the new door because the hole for the wire loom can't be cut with the door in place. It was now easy to cut the hole and reinstall the grommet. Convertibles have a second set of latches for alignment. I found the indents for the latch on the new door and installed the pieces. The door went back

on easily and fit half way OK. A few attempts and as I went tight on the bolts the door drew itself into position -- I hope

I remember for next time when adjusting a door to wait until bolts are tight before deciding if it needs further adj. We'll leave the door at this point while we collect parts (regulator spring, cat whiskers, window channel liners).

Following Don Verity's torque advice, I worked on the transmission pan. All the bolts took 8 ft-lb. I moved

up to 13 and one bolt in the front let go.

It had been damaged before; there was no chance to save it.

Ace mechanic Jamie installed a heli-coil. I have not refilled the transmission so we

will yet to learn if the stripped bolt was the cause of the leak.

Following Don Verity's torque advice, I worked on the transmission pan. All the bolts took 8 ft-lb. I moved

up to 13 and one bolt in the front let go.

It had been damaged before; there was no chance to save it.

Ace mechanic Jamie installed a heli-coil. I have not refilled the transmission so we

will yet to learn if the stripped bolt was the cause of the leak.

We started painting transmission buttons and turn signal RL knob (green). I brought over my 3 tubes of cat whiskers and only 1 fits so I will get more. Quirey sold that business to AMS, the old Frank Mitchell. They say $160 for a set. It was $130 in 2023 so I guess that is not bad.

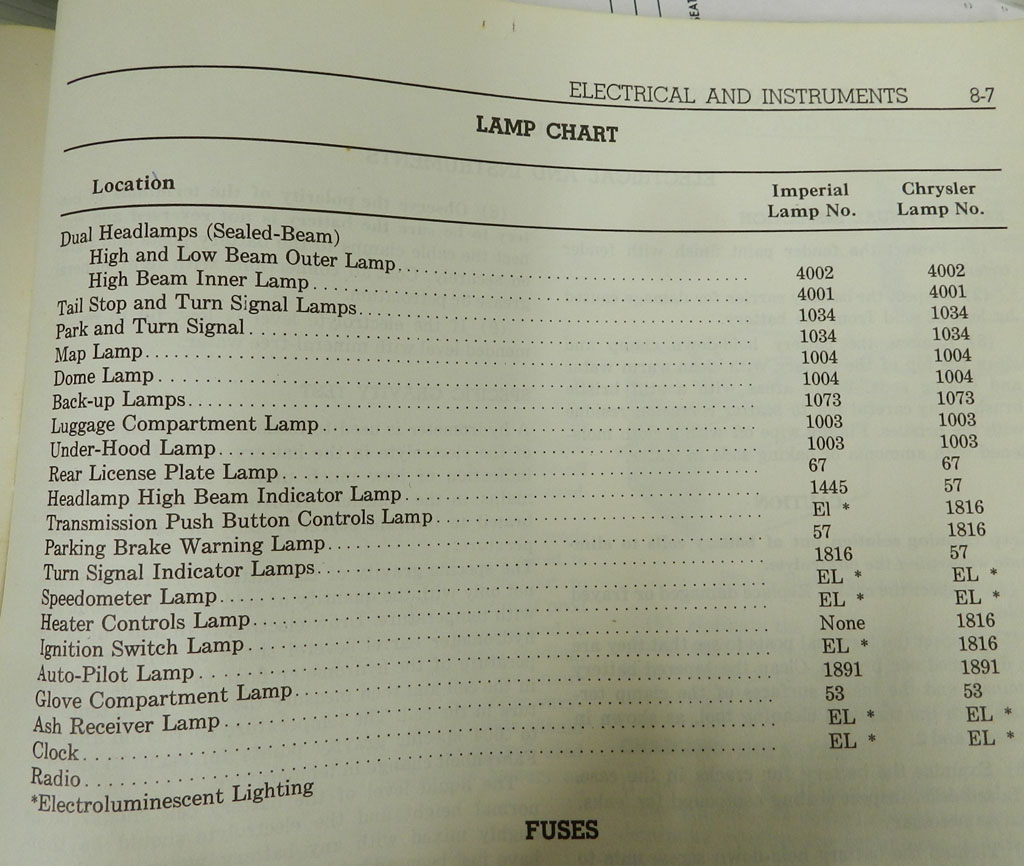

I removed the heater button assembly to replace the switch. The job wasn't too bad although there were the normal wrestles with the Bowden cable, the retaining clip, the vacuum tube bundle and the wires. The new switch buttons work smoothly. The heater fan motor has squeaks at low speed but works all 3 speeds. The temperature regulator Bowden works good. I am not satisfied with the amount of light coming out of the heater button faces. I checked the lamp, it is the right one (#1816) (38 lumens). I replaced with a new one but no improvement. I tried with the lamp tube removed, with reflective aluminum added, but there is still not a lot of light out of button heads. I may try an LED some day.

I received the transmission and heater switch light barriers from Quirey. The flat one fits under the heater switch, the folded one is for the transmission buttons. We have a video.

|

|

We are looking at the felt barriers around the push buttons. The same piece fits 1960-1962 transmission and heater control buttons. These barriers keep the buttons from rattling and prevent light from leaking around the sides when the headlights are on. They are often in poor shape these days. I am looking into making new ones.

It is fairly easy to replace the felt barrier (and the light shield) in the transmission button pod. The heater switch is more involved -- the assembly won't come far out of the dash before something (Bowden cable, vacuum lines, wires) holds it back. Installing either the felt barrier or the light barrier requires the switch be unscrewed from the base. While this is not a terrible task, access is limited.

At the shop, removed the regulator from the manual window door but the spring is smaller (2.5" diameter) than the power (2.75" or more). It appears I will have to get a regulator from a power window car.

We decided to change both rear axle seals (inner). The passenger side seal was difficult to remove. Driver side seal easy to remove and was leaking. Checked bearing races, all good, repacked bearings and reinstalled.

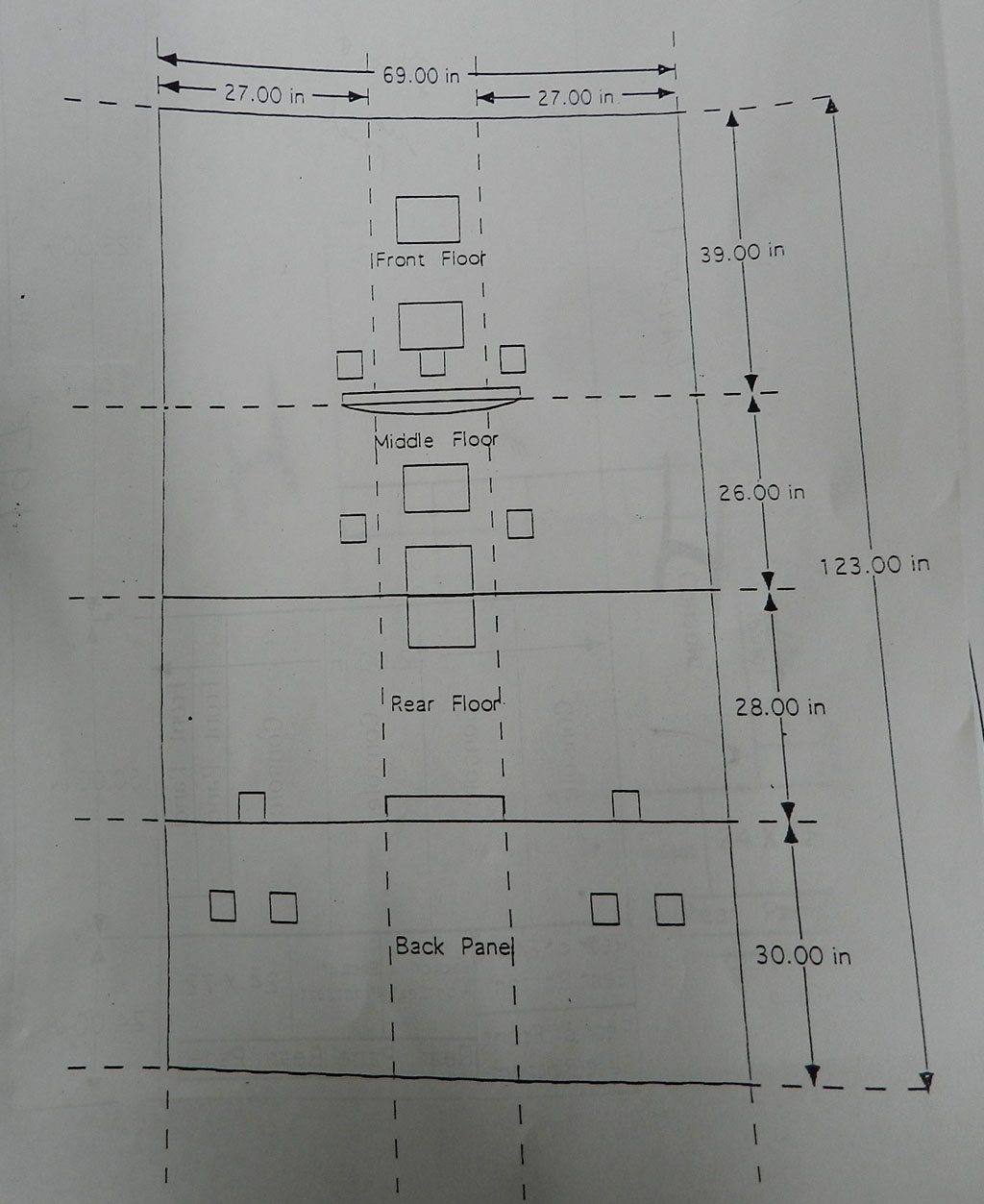

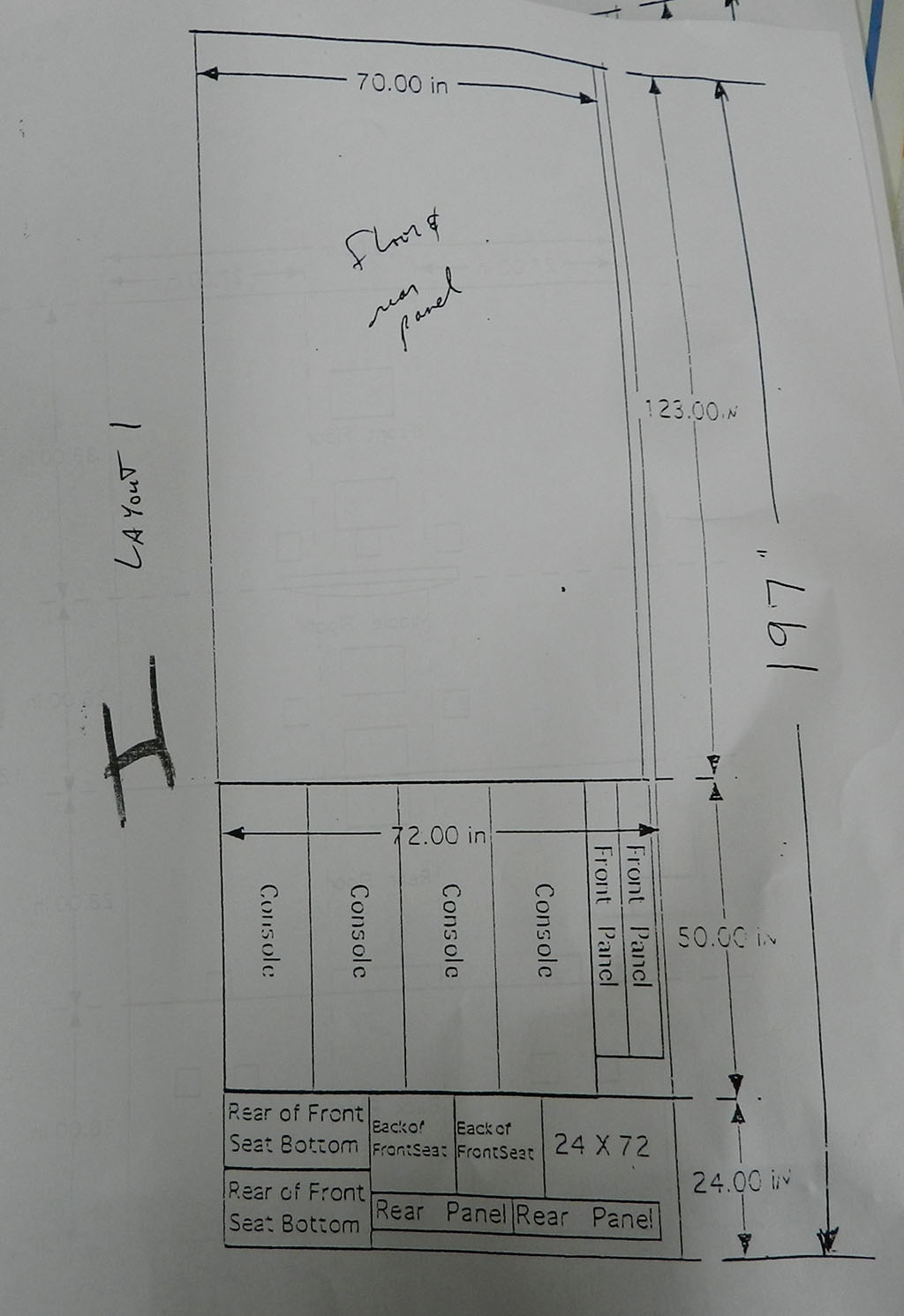

The carpet in these F G H cars -- The F and G

use black carpet, the H uses gold. The club (George Riehl, Ken Mack, Michael Burke) researched this subject

in 1995. While the G carpet has a pile height of

.375" and was available anywhere, the black F carpet has a different pile (.500")

and could not be found. The H carpet is a .375" pile but the color was

unique and could not be found. So the club took on

a project to have F and H carpet custom made. We had a batch made and sold

kits through the club store. 34 F kits were sold with the last one being

sold in 2002. 16 H kits were made, the last sold in 1999.

Each F kit consisted

of 5 yards of 72" wide material. The H kit was 5.5 yards; slightly more because the front seat

backs also needed material.

A layout was provided to show how the kit

could be cut into parts. A while after the last kits were sold, we approached

the manufacturer for another production run. They would not make another and no

other sources were found.

I bought several carpet kits back then and still had one I could use on

this car.

Back

|

|