Page 10

Installed new quarter window gaskets. The old one just pull out, new ones push in the groove. They fit tight, no adhesive needed. New ones are flocked, look good. The passenger side seals great, the driver needed a little adjustment. I should probably plan that glass will need adjustment after new seals -- new seals being thicker will press the glass out at the top.

Don Verity pointed out that I was missing the rubber bumpers for the gas filler door. I had never seen one and didn't see a listing in the Goer's catalog. I found a #19 Goer's door stop bumper in spare parts and modified so it works as the gas door bumper.

|

|

|

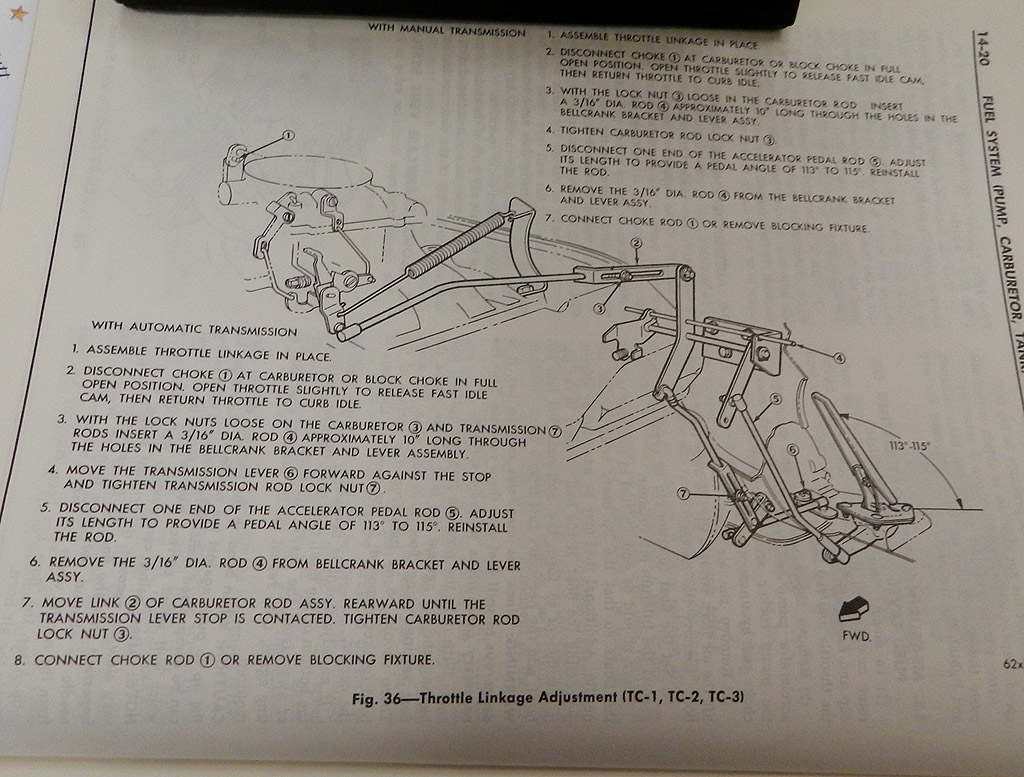

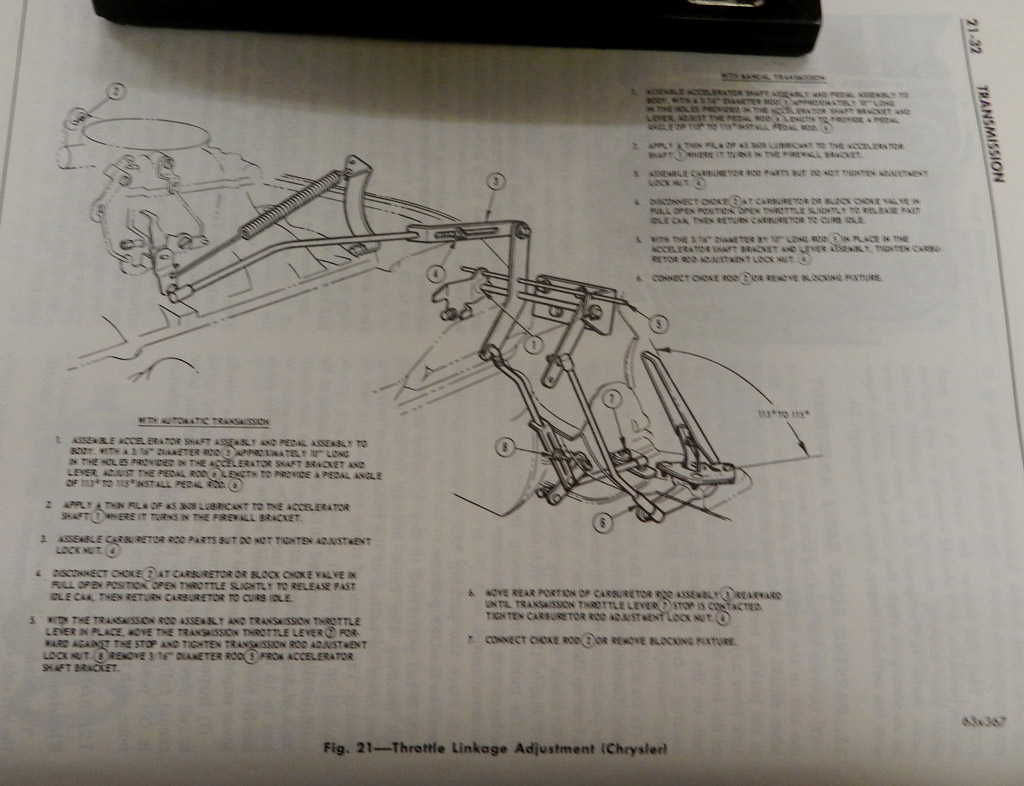

With the new single 4bbl AFB, the throttle linkage isn't right -- the gas pedal doesn't have full travel. I found the correct link in spares and adjusted the linkage until I got a good gas pedal with both idle and WOT. I needed a throttle return spring, made several from universals. None of them worked and ended up using an original. The same spring was used on the V8s across the model line 60-64. Time to adjust the transmission kick down and I didn't find what I wanted. Turns out you don't want the diagram in the transmission section, page 21-32. You want the diagram in the fuel section page 14-20 for the proper procedure. I set the transmission link via the manual. For a 3/16" dia rod, use a chain saw file. It fits fine.

|

|

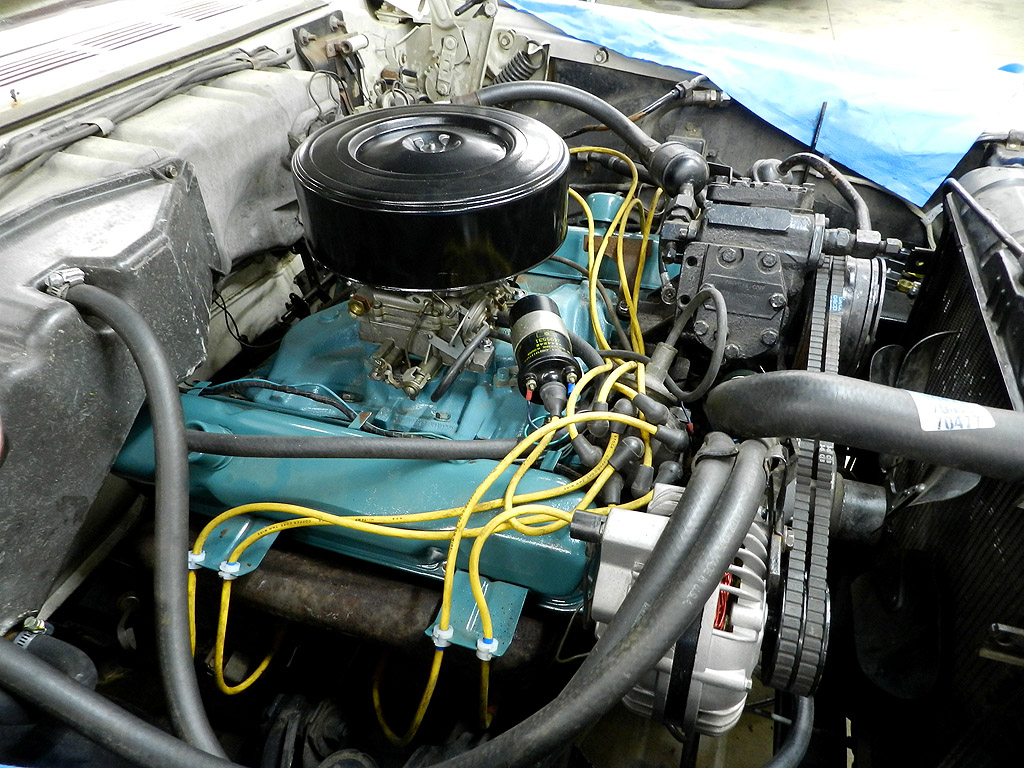

I had spark plug wire insulators in stock from R/T Specialties, part number 2098980 which fit the spark wire holders mounted in the valve covers. Turns out the wires the previous owner used are smaller diameter and had to be taped so the insulators would bite but OK for now.

I decided to change out the throttle pivot bushing. When you depress the throttle, the pivot shaft moves toward the open end of the bushing and that is where you see the most wear. You can see it in these pictures. I installed one of the new 3D printed bushings I got from Charlie Valentine (the black piece). It is a bit difficult to access the pivot bracket; you pretty much have to be half body over the fender into the engine bay.

Back again to the slight leak from the transmission. Removed the pan and the reusable gasket. D Verity mentioned

possibility the trans pan bolts are too long. I measured and they all the same length. I found the blind holes in the casing, measured the depth and the bolts are short enough so they won't bottom out.

I decided to install a new cork rubber gasket, torque, remove and look for impressions -- if there were areas where I didn't have impressions, I didn't have compression. I torqued to the book spec of 150 in lb, removed and could not see any impressions anywhere; the idea didn't work. Cleaned things up, used a little RTV on the outer half of the gasket top and bottom side, installed on pan. RTV does a great job of holding the gasket on pan for location and bolt holes. Installed, torqued to 150 and let it sit overnight.

The next day I added the transmission fluid and the day after checked for leaks.

possibility the trans pan bolts are too long. I measured and they all the same length. I found the blind holes in the casing, measured the depth and the bolts are short enough so they won't bottom out.

I decided to install a new cork rubber gasket, torque, remove and look for impressions -- if there were areas where I didn't have impressions, I didn't have compression. I torqued to the book spec of 150 in lb, removed and could not see any impressions anywhere; the idea didn't work. Cleaned things up, used a little RTV on the outer half of the gasket top and bottom side, installed on pan. RTV does a great job of holding the gasket on pan for location and bolt holes. Installed, torqued to 150 and let it sit overnight.

The next day I added the transmission fluid and the day after checked for leaks.

Just for kicks, I checked to see if the console tach worked. I put a drill on the distributor end and spon the cable. Nothing. Ran the drill the other way. Nothing. Disconnected the cable from the tach and out came a broken segment of cable. New tach cables are available.

|

|

I found a used J tach. I tested, it works, cleaned it up and installed. It is very difficult to install in the console once the console is already in the car -- blind access to the three 3/8" studs and awkward stance with the interior installed. Installed the bulb and the cable. Getting that fiberglass panel on with those 6 push pins is very hard. Those pins don't want to go. They are all back in.

|

|

|

|

The old master cylinder was leaking so we got a new one from Rock Auto and installed. I see the top cover says BREAK FLUID USE ONLY DOT3. ??Break fluid?? Notice the master has a spring loaded push rod and that the mounting flange has bolts. Normally the mount has holes to receive studs from the booster, but being a remote booster, this is essentially manual brakes. The new master has the dreaded lower port that has to be plugged and always leaks. This one doesn't.

|

|

|

|

.jpg)