|

|

|

|

|

|

|

|

|

|

|

1965 Chrysler 300L

Page 4

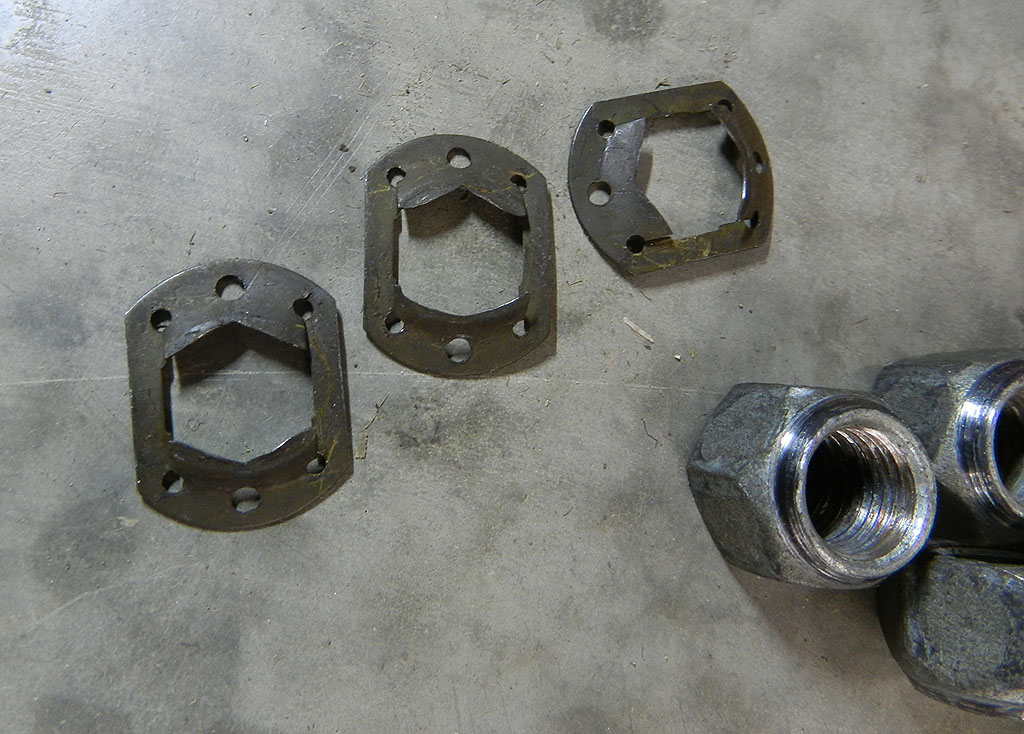

The left hand thread lug nuts on both wheels are in great shape too. On the rear brake hub, we found 3 of the clips used at the factory to hold the drum onto the studs during assembly. These clips are either rusted away or discarded on the first brake job. These clips are in great shape and will be used again.

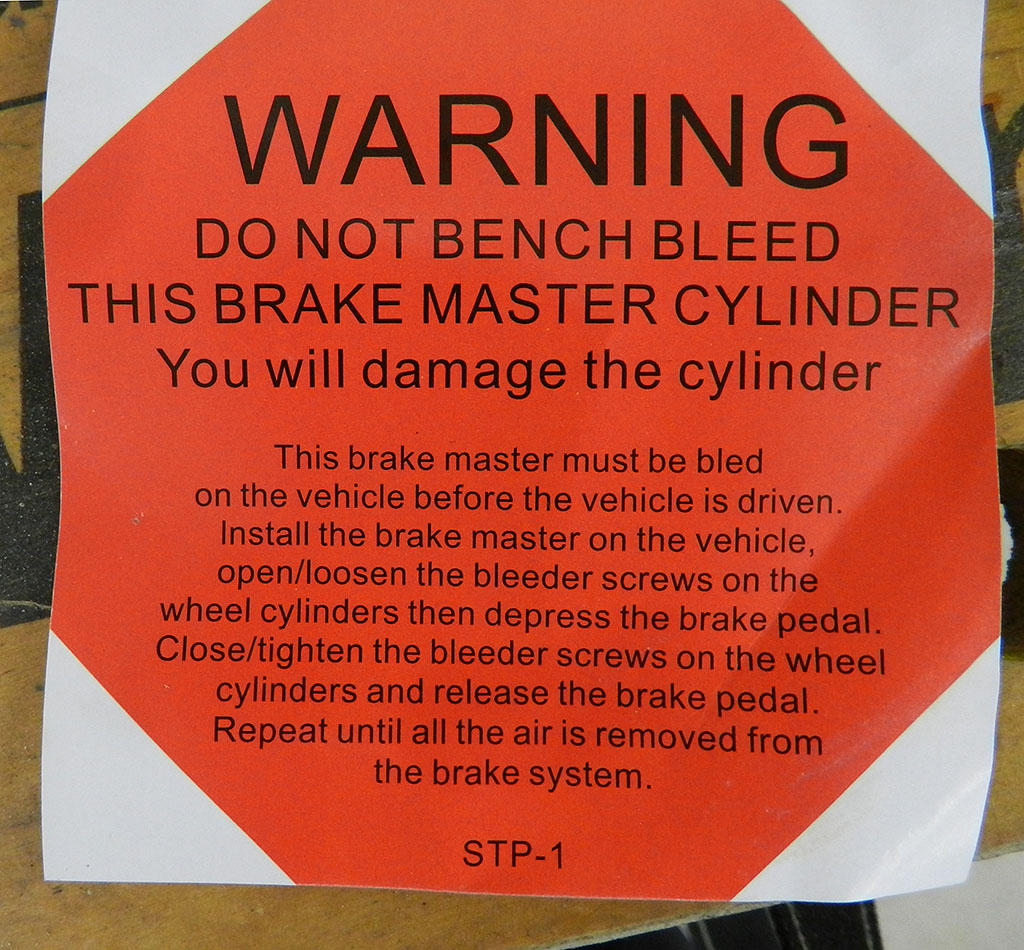

The brake shoes front and rear still have good lining. Wheel cylinders are not leaking but have junk under the cups. New wheel cylinders and brake hoses are in process.

I found a minor oil leak under the engine. It turned out to be the oil pan drain plug. This one had a hard copper washer and I think that copper washer was the trouble. I got a new plug with a Nylon washer

and it stopped the leak.

I added 1 gallon of new antifreeze and it would not take more. This is a 17 quart system and was near empty so I think there is an air pocket in the system. We got the engine running (briefly) to see if that would break the air pocket. It did not. The level in the radiator rose and went out overflow but coolant did not circulate. I think we will have to remove the thermostat (180 degree) and replace with one that has a vent.

I came back a week later to drain the coolant and change the thermostat. I took off the cap and the coolant was gone. On a whim, I added 1.5 gallons before it was full. Apparently the air pocket worked its way out during the week. Isn't it great when things fix themselves? We have a video of the hoses, belts, tension tools and thermostat.

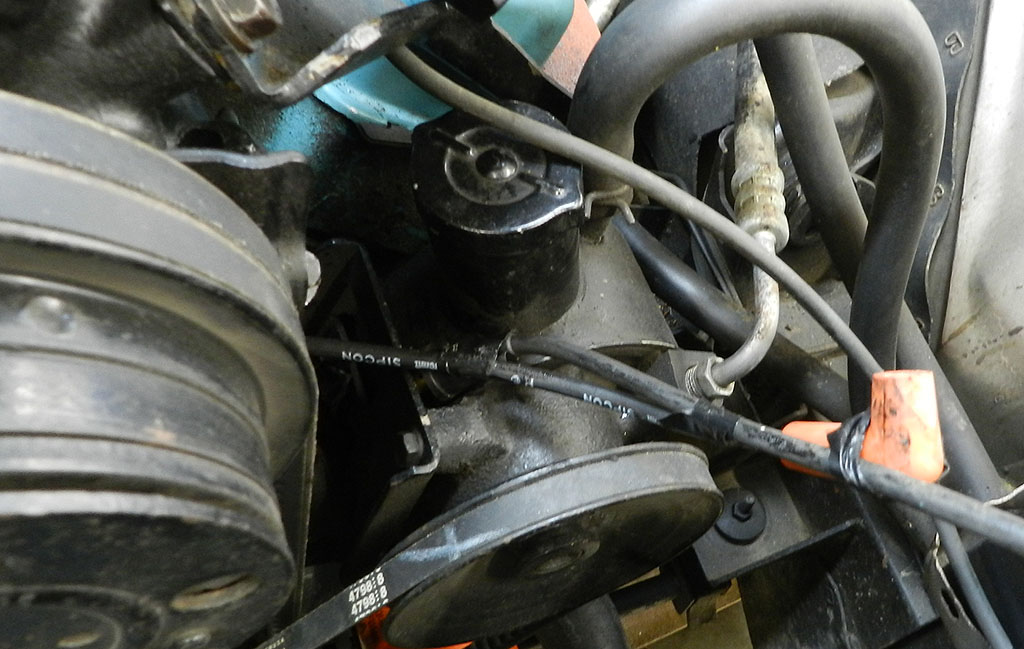

The plug wires looked OK but I had a set of supposedly correct wires so I thought I would install them.

This was a Motorcraft set, # WR-3832. The passenger side on these cars with AC is pretty much a breeze with the exception of cylinders 6 & 8. The new wires all have 90 degree boots but cylinders 6 & 8 need straight boots so that the wires sit high and away from the exhaust manifold. For now #8 wire was long enough to route with the 90 degree boot so it wouldn't cook but #6 was not. I reused the original wire for #6.

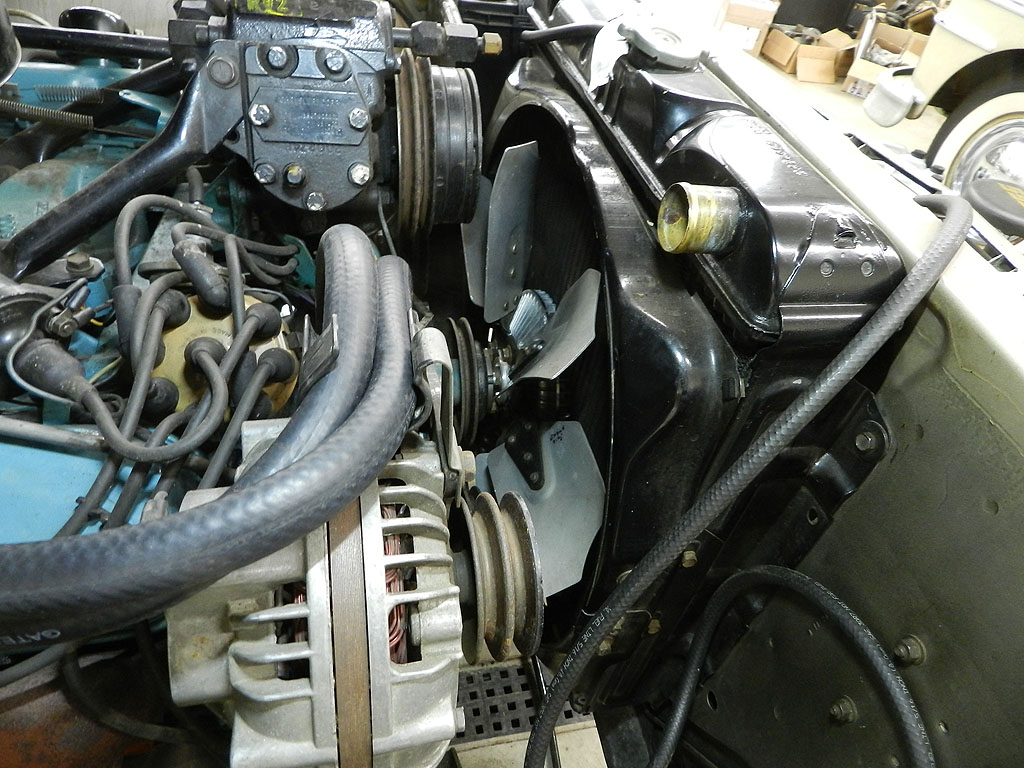

New upper and lower radiator hoses are installed. The Corbin clamps are replaced with reliable steel screw band clamps. New heater hoses are installed. The hoses coming off were still pliable. The fan clutch is original and while

in good shape, it makes sense to replace it with a new one. If you order off Rock Auto they say use a Hayden 2707. Don't. It is too tall. You want a Hayden 2947. Even then, getting the bolts onto the water pump is tricky. You can easily get the first bolt

on but you need to leave space so the clutch can move off of the water pump flange. Otherwise the heads on the other

bolts won't clear the back of the clutch.

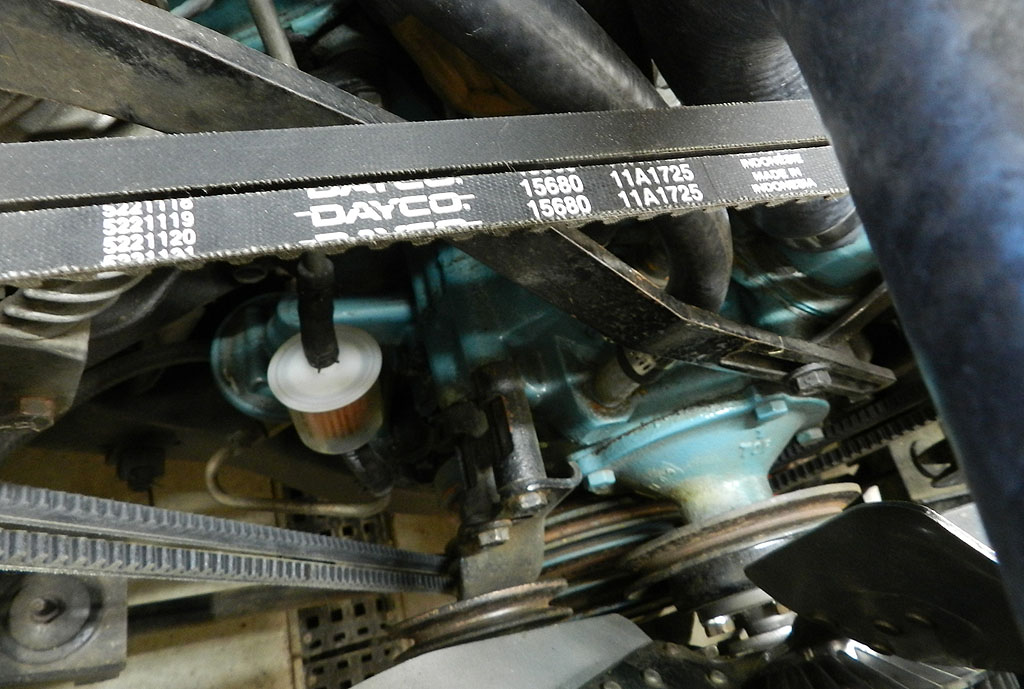

Time for new coolant and new belts. The standard Rock Auto power steering belt fits fine. The fan belt does not. Rock says 15348 but this is too short. You want a 15360 (perfect) although a 15370 will work.

Dayco 15680 fits nicely for the AC-alternator;

the adjuster ends up in the middle on a new belt. Installed

the adjuster ends up in the middle on a new belt. Installed

the new upper rad hose after cutting something like 1.5" off of both ends.

There is a difference in which end of the hose goes to the block--look carefully for the twist in the molded hose giving clearance to the heater hoses. Best to put all the belts on, AC first, then power steer then fan. Best to tension power steer first because the AC belts block the power steer locking bolt.

the new upper rad hose after cutting something like 1.5" off of both ends.

There is a difference in which end of the hose goes to the block--look carefully for the twist in the molded hose giving clearance to the heater hoses. Best to put all the belts on, AC first, then power steer then fan. Best to tension power steer first because the AC belts block the power steer locking bolt.

The true terror on these AC cars is routing the plug wires for 1 3 5 & 7 under the AC compressor. I was able to tape the new wire to the old and thread it through. Getting the new wire boot taped to the old wire in such a way that it would act

as a plow was key. Otherwise the boot face found every opportunity to butt against things.

I was not thrilled with these new wires, that all of them had 90 degree boots and some of the wires are too long by several inches. I had expected better from a kit that was specific to 1959-1965 Chryslers.

We have a video of this adventure.

|

|

|

To page 5