Page 4

| I decided the next thing was the back seat area. Rear window chrome was removed, polished and reinstalled. The rear seat was removed for access to the quarter windows, which were inoperative. Pleased to find the floors in solid shape. |

|

| Under the rear seat was the build sheet. It was really wedged between the cushion and the springs. No amount of coaxing could remove it without tearing. |

|

|

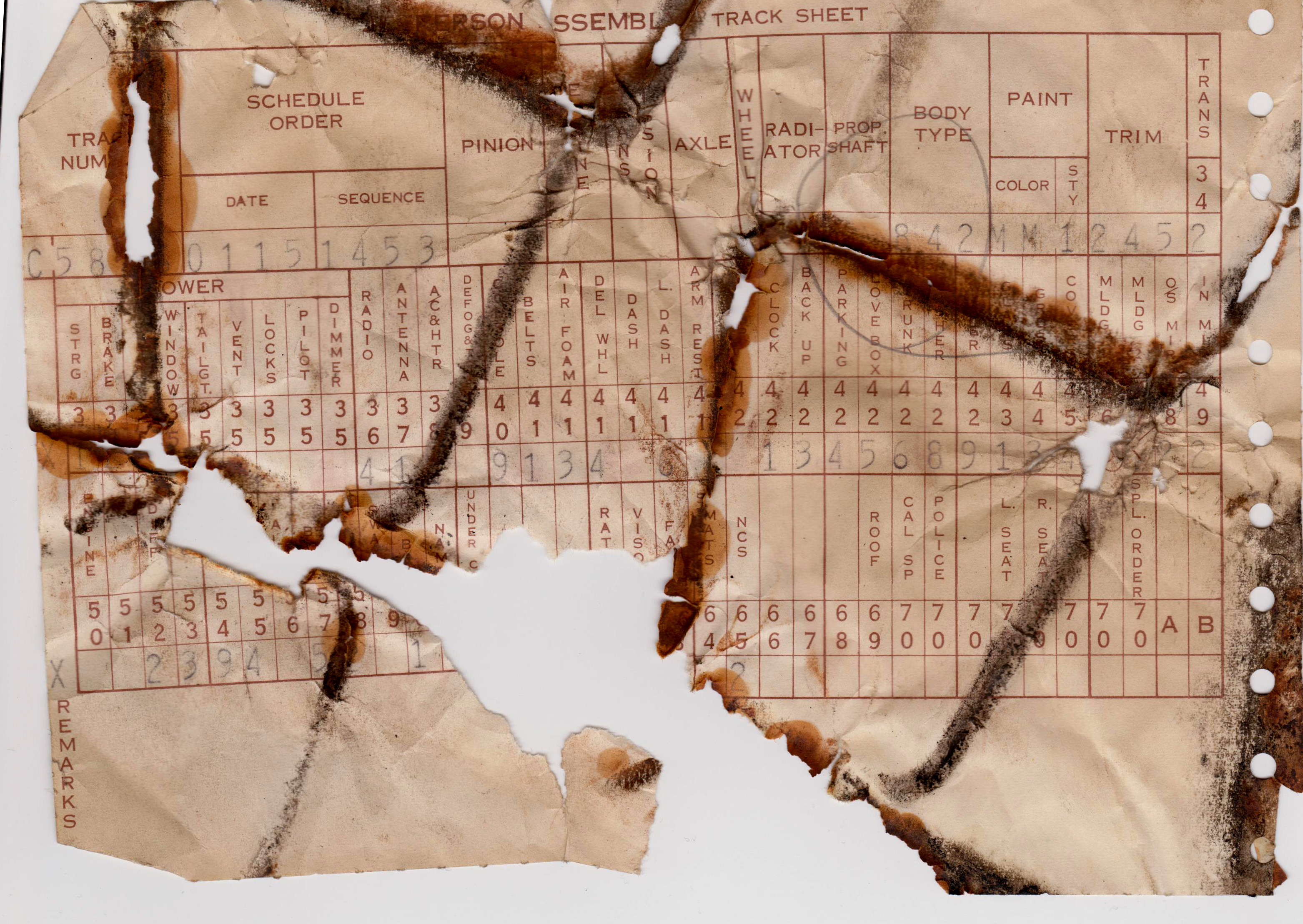

Here is the build sheet.

Turns out it is a build sheet for a J but not for this J. Body type 842 means 2 door coupe 300J but paint MM1 means alabaster and this car is black. Also the schedule order date of 0115 (Jan 15) is far from the car's build date of 04/17/63. How this seat got in this car I can only guess, but possibly a previous owner swapped rear seats. Click here for Carl Bilter's decode of this build sheet. |

|

| The passenger side window needed only lube, but the driver side wasn't as easy. |

|

| The window motor was rusted beyond repair. I had spare motors and installed another. The first time I tested it, the window went down and went right back up. I've never seen that before. I tested it again. The window went down and right back up. Turns out the switch was bad and wouldn't center after release. |

|

| For the first time in 20 years, all the windows work. |

|

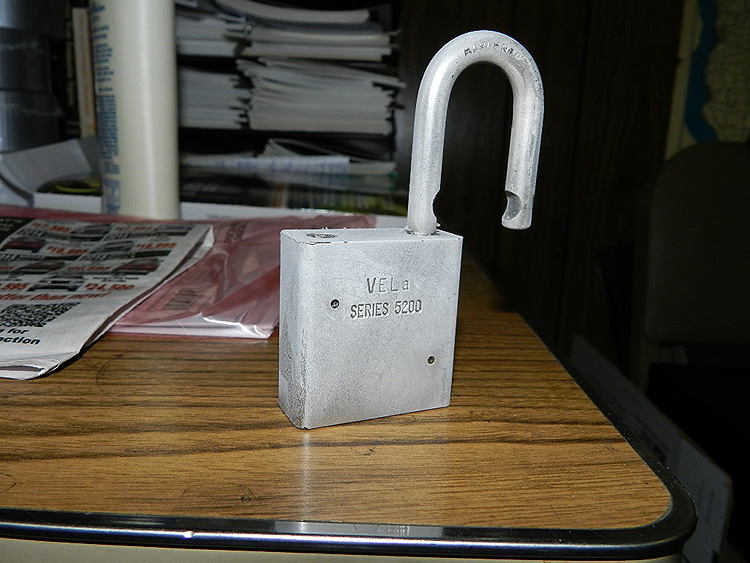

| The day I chose to work on the windows, it was minus 21 degrees. This is the lock off of the gate to demonstrate how cold that is. |

|

| Getting the front end back together. Found the driver front turn signal doesn't work. It worked before I took the bumper off. Checked the lamp, the socket, the ground, all OK. Passenger side works fine. |

|

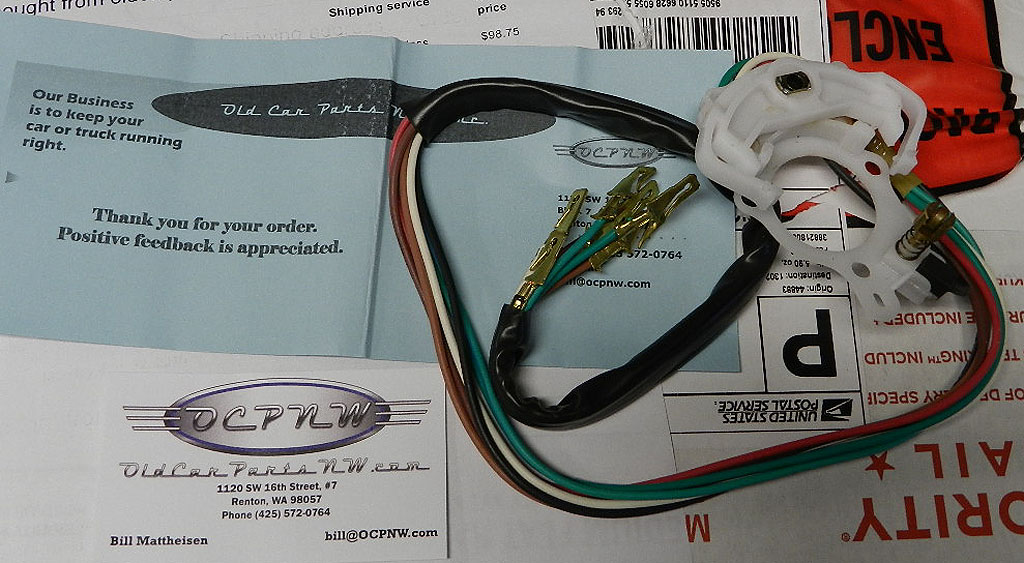

| It took a while to determine the turn signal switch needed replacement to fix the turn signal problem. A new switch came in from OCPNW and will go in next weekend. |

|

| Time to check the rear brakes. Hubs were removed and the shoes checked. New wheel cylinders are coming. |

|

| The headlight switch was replaced with a new one (DS165) and now the instrument panel lights work. While I had the switch knob out, I repainted the center with a bunch of light coats, flat black paint. |

|

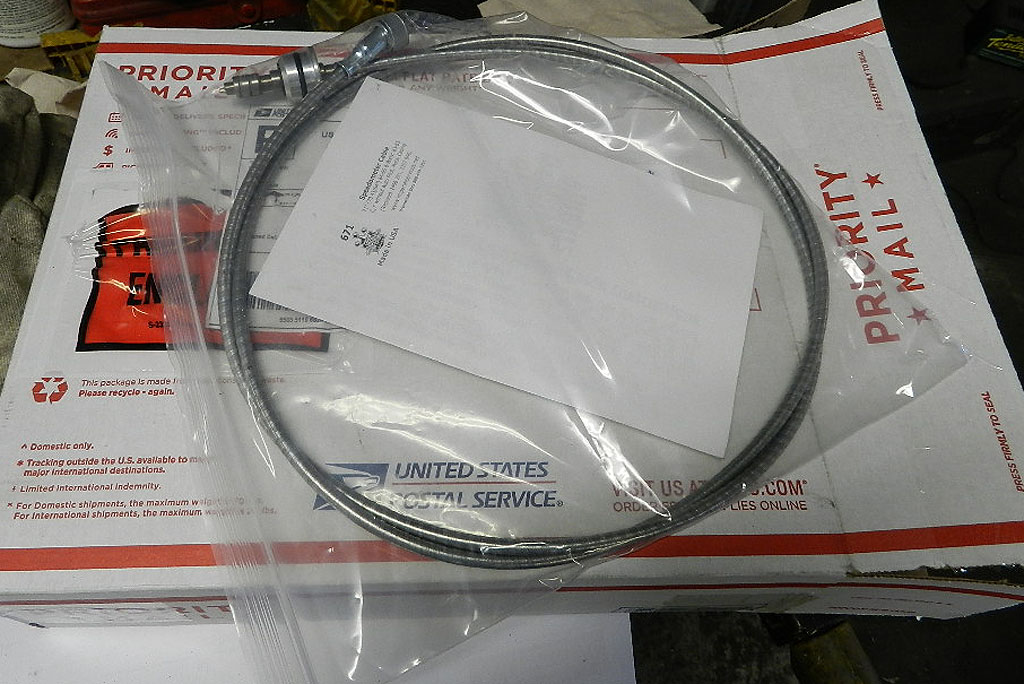

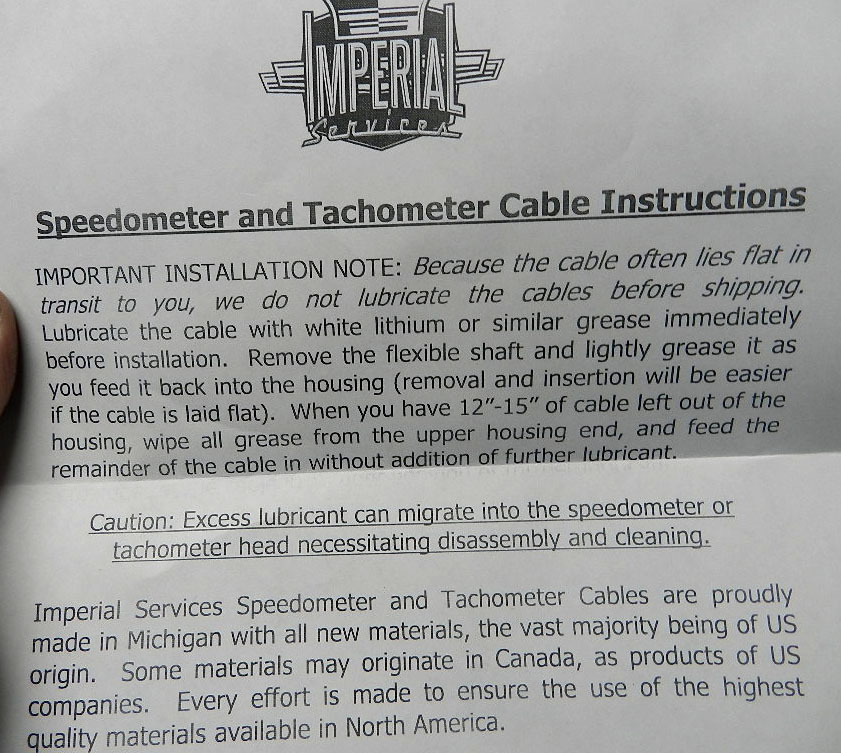

| The speedometer cable was broken so a new one came in from Murray Park. Installation was straight forward. |

|

| Before installation, I followed the instructions and lubed the new cable. |

|

|

Rear brake drums were checked

and then prepared for paint.

On the other end of the car, the new turn signal switch was installed. |

|

| I used Eastwood chassis black gloss. Lug stud threads were chased with RH and LH dies to remove years of dirt. |

|

| New brake cylinders, shoes and parking brake cables for the rear brakes. |

|

| A new transmission shift cable is installed. |

|

|

Working on the front brake drums.

Now I know where Darth Vader got his helmet. |

|

|

The J is getting smaller.

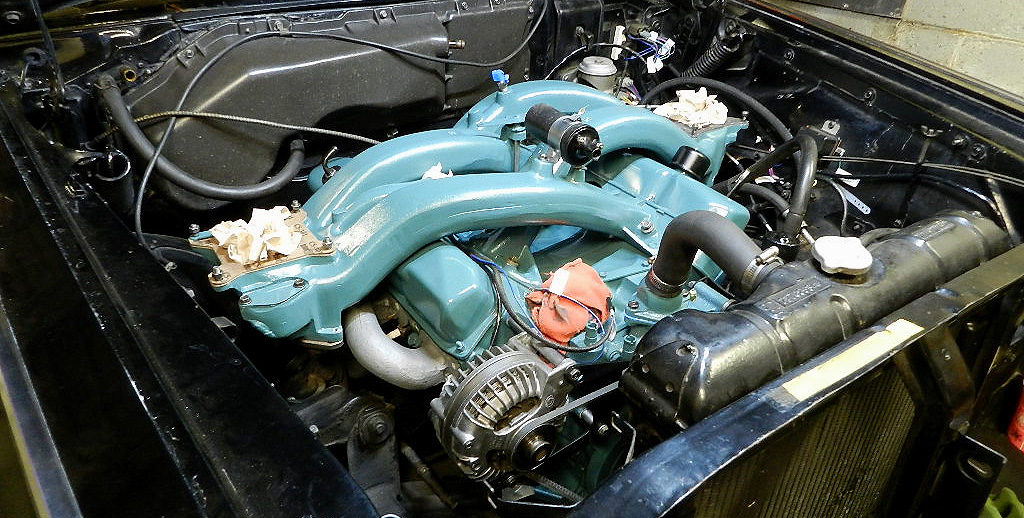

When parts come off the car it seems to explode. Boxes and shelves are needed to store things (and to lose things). Now that parts are going back on, the J gets smaller. Brakes are reassembled, the system is bled. Fan, alternator and power steering pump are on. Rams are on but loose so connections and adjustments can still be made. |

|

| Balance tube installed. Helps to heat the rubber hose couplings so they flex enough to install. Clamps and rams are still loose so heat tubes can be connected. |

|

| I made stainless steel block off plates to eliminate carb heat. These slide in easily between the heat tube and the ram, held in place by the studs and ram gasket. |

|

| If you look closely you can see the heat tube, gasket, and plate. |

|

To the next page

Back